1. Industry overview: The core carrier of multifunction packaging solutions

As a packaging solution that combines strength and flexibility, cardboard boxes have shown strong vitality in the global market in recent years. Its main raw materials are high-strength corrugated paper or jam paper, which has strong compressive resistance and easy processing and printing characteristics. It is widely used in food, cosmetics, electronic products, gifts and other fields. According to the differences in usage scenarios, the industry has formed a mature product classification system:

Ordinary cartons: adopt a single-layer cardboard structure. With its low cost and easy folding advantages, it has become the first choice for food packaging and daily necessities transportation, such as common fast food boxes and supermarket retail cartons.

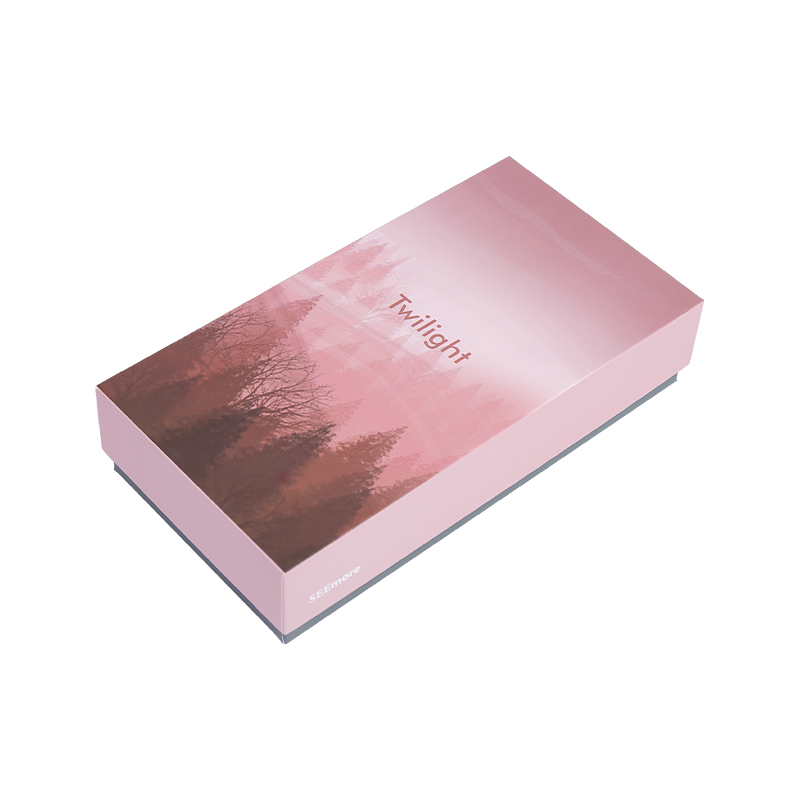

Colored cartons: Use colored paper as the base material, and presents brand visual elements through high-precision printing technology. They are mostly used in high-end gifts and cosmetic packaging, such as perfume gift boxes, jewelry boxes, etc., to help upgrade the brand image.

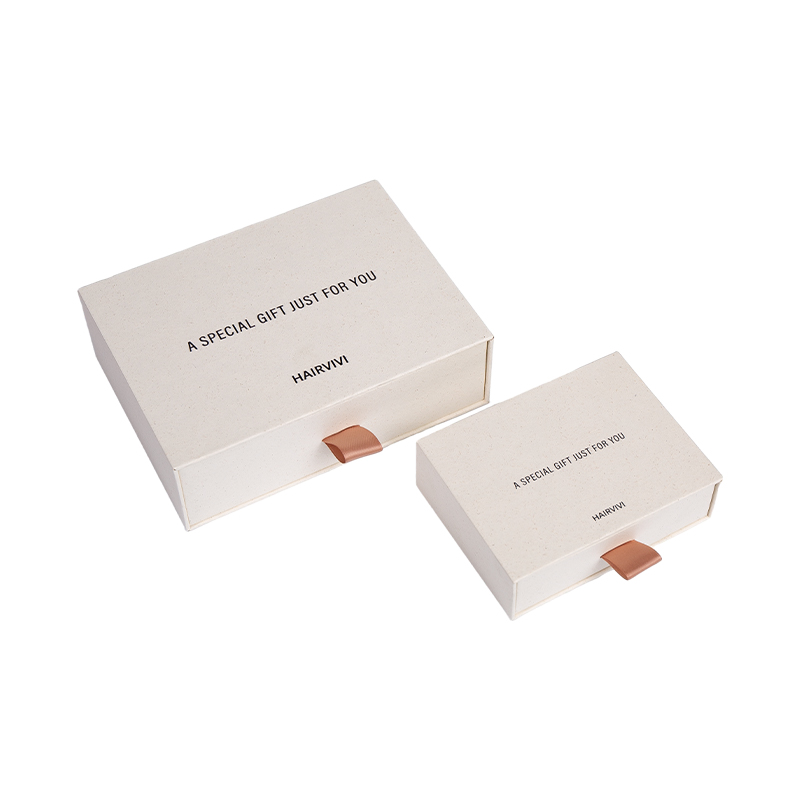

Paper sleeve box: Innovative drawer design, consisting of a bottom box and an outer cover, and a reinforced cardboard structure inside, suitable for products with high protection requirements, such as mobile phone packaging boxes and leather shoe gift boxes, both aesthetics and practicality.

Folding carton: It adopts multi-layer cardboard composite technology, and the foldable storage characteristics make it occupy an important position in small product packaging such as tissue boxes and glasses boxes, effectively saving storage and transportation space.

2. Core advantages: the perfect fit between green economy and customized demand

Driven by the dual driving of global environmental protection trends and consumption upgrades, the core competitiveness of the cardboard boxes industry is becoming increasingly prominent:

(I) Environmental protection attributes are in line with the sustainable development goals

As a recyclable and degradable packaging material, the production raw materials of cardboard boxes can be recycled by waste paper, greatly reducing the consumption of forest resources. Data shows that about 70% of carton waste worldwide is recycled every year, complying with the EU's Packaging and Packaging Waste Regulations (PPWR) and the US EPA environmental standards. This feature makes it a mainstream choice in the transformation of "green packaging" in the e-commerce and fast-moving consumer goods industries. For example, an international beauty brand has fully adopted recyclable cartons to replace plastic packaging, with a carbon footprint reduced by 35%.

(II) Customized production meets the needs of diversified scenarios

Industry-leading companies realize the full process customization from size, shape to graphics and text through digital printing technologies (such as UV printing, gold stamping technology) and intelligent cutting equipment. Typical cases include:

Special-shaped structure innovation: Heart-shaped and animal-shaped cartons launched by the chocolate brand have enhanced product attractiveness through 3D die-cutting technology, and sales in the festival market increased by 20%;

Functional upgrade: Medical tape packaging box introduces easy-to-tear strip design, and electronic equipment packaging box adopts anti-static lining to meet the professional needs of special industries;

Brand narrative enhancement: The tea gift box presents traditional cultural patterns through gold stamping, and the maternal and infant product packaging adopts soft tones and cartoon elements to enhance the emotional connection between consumers.

3. Market trend: Two-way expansion of technological innovation and application scenarios

At present, the cardboard boxes industry is undergoing a critical stage of technological iteration and market expansion, and two major trends are worth paying attention to:

(I) Intelligent production improves efficiency and accuracy

The application of Industry 4.0 technology promotes the industry to transform into automation and flexibility. For example, some companies have introduced AI vision detection systems to monitor the color deviation and seam strength of carton printing in real time, and the scrap rate is reduced to below 0.5%; digital printing equipment realizes rapid version replacement in "small batches, multiple batches", and the shortest delivery cycle is compressed from 7 days to 48 hours, meeting the urgent needs of e-commerce platforms for customized packaging.

(II) Emerging markets and cross-border applications bring incremental space

In emerging consumer markets such as Southeast Asia and the Middle East, with the rapid development of retail and e-commerce, the annual demand growth rate of cardboard boxes has reached 8%-10%. At the same time, cross-border integration cases in the industry are frequently seen:

Cultural and creative field: The replica carton of cultural relics launched by museums and designers, restores cultural relics details through high-precision printing and becomes a new carrier for cultural IP derivative products;

Fresh cold chain: The breakthrough in waterproof coating technology enables cartons to be used for fruit and vegetable transportation, and can be kept fresh for 48 hours with ice bag lining, reducing fresh food loss rate;

Luxury packaging: High-end watches and perfume brands adopt magnetic buckle hard box design, combined with velvet lining and silver hot-silver craftsmanship to create a luxurious experience of "unboxing ceremony", with a unit price of 3-5 times higher than that of ordinary cartons.

4. Conclusion: Seize structural growth opportunities in change

With the stricter global environmental regulations and the improvement of consumers' requirements for packaging aesthetics, the cardboard boxes industry is transforming from a "standardized product" to a "brand value extension carrier". For enterprises, deepening green supply chain management, investing in digital customization capabilities, and developing high-value-added application scenarios (such as luxury packaging and cross-border e-commerce special boxes) will become the key to breaking the situation. For upstream and downstream participants in the industrial chain, grasping the dynamic balance between technological innovation and market demand may take the lead in this "packaging revolution".

中文简体

中文简体

English

English