Under the wave of consumption upgrading, customized tote bags have become a popular choice for brand marketing and personalized consumption with their unique design and high-quality attributes. For custom tote bag suppliers, the exquisiteness of the core technology directly determines the market competitiveness of the product. Among them, the two major processes of hot stamping printing and hand sewing, relying on their ultimate pursuit of details, give the tote bag high-end texture, becoming the key factor in shaping brand value.

1. Hot stamping: visual expression of luxurious texture

1. Process Principles and Technology Evolution

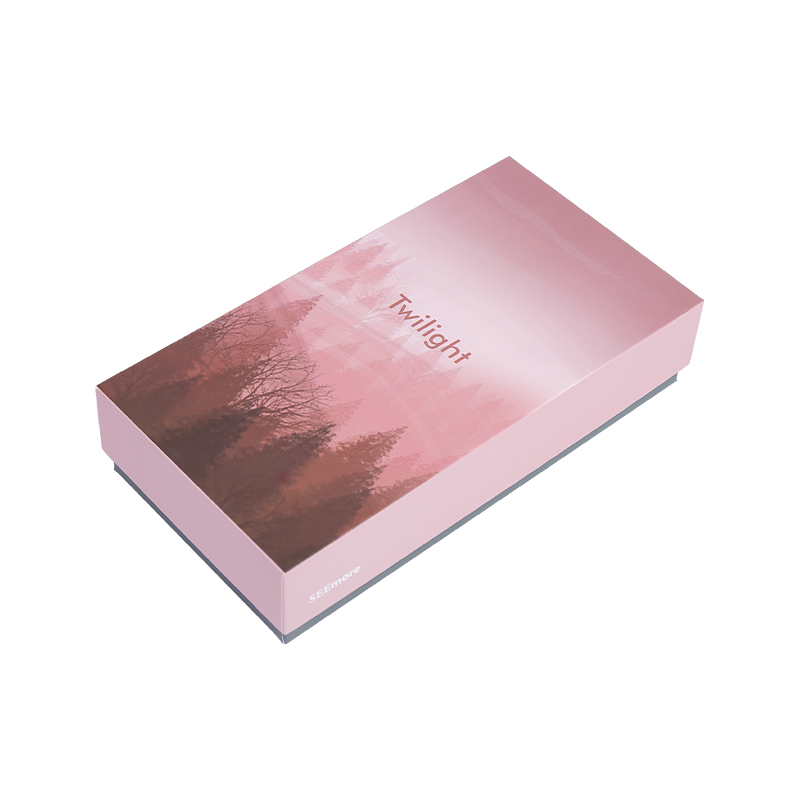

Hot-pressure transfer printing, also known as hot-pressure transfer printing, is the principle of transferring metal foil or pigment foil to the surface of the fabric through high temperature and high pressure to form a bright graphic effect. Early gold stamping technology mostly adopted traditional letterpress printing, relying on mold pressing, and the pattern flexibility was limited; while modern custom tote bag suppliers widely used digital gold stamping technology, and through computer control, it can achieve one-time molding of high-precision and complex patterns, greatly improving production efficiency and pattern fineness. For example, complex brand LOGOs and delicate floral patterns can be accurately presented through digital gold stamping technology, meeting the strict requirements of high-end customers for visual effects.

2. Material selection and color matching

The texture presentation of the gold stamping process is closely related to the selection of materials. The material of metal foil (such as gold foil, silver foil, rose gold foil) directly affects gloss and durability. Suppliers usually choose high-quality foils that are resistant to high temperature and oxidation to ensure that the tote bags are not easy to fade or peel off during daily use. In addition, the choice of fabric substrate is also crucial. Smooth and dense silk, cotton or imitation leather fabrics can better fit with metal foil and highlight the three-dimensional feeling of the gold-plated pattern; while rough linen fabrics need to be specially pretreated to enhance the adhesion of the foil. In terms of color matching, high-end customized tote bags often use low-key and luxurious color schemes, such as the combination of black gold, champagne gold and dark fabrics, which not only highlight the brand style, but also avoid visual scatteredness.

3. Quality control and detailed processing

In order to ensure the quality of the gold stamping process, customized tote bag suppliers need to establish a strict quality control system. From color calibration in the pattern design stage, to temperature and pressure parameter monitoring during the printing process, to wear-resistant testing of finished products, every link needs to be accurately controlled. For example, excessive high temperatures may cause fabric deformation or metal foil to bubble, and insufficient pressure will cause blurred patterns; in detail processing, for edges, corners and other parts that are prone to burrs, multiple ironing or manual trimming is required to ensure that the edges of the pattern are neat and smooth, so as to maximize the exquisiteness of the gold stamping process.

2. Hand sewing: inheritance of the quality of craftsmanship

1. The unique value of hand sewing

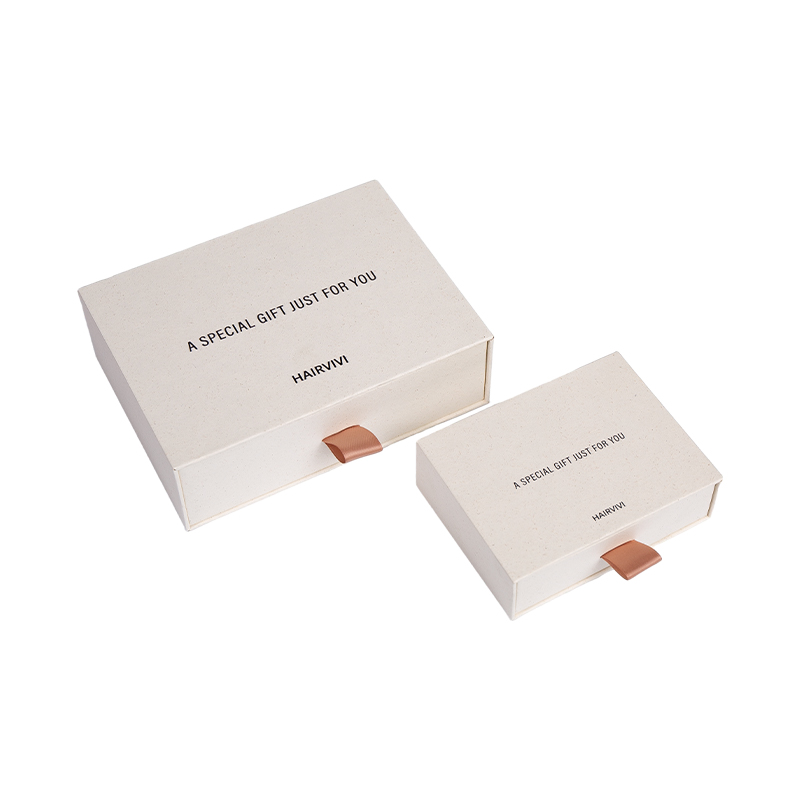

Today, with the popularization of industrial production, hand sewing is still the core competitiveness of high-end customized tote bags. Compared with machine sewing, manual sewing pays more attention to the delicateness and accuracy of each stitch, and can flexibly adjust the needle method according to the characteristics of the fabric to avoid possible broken or jumper problems in machine sewing. Especially for tote bags with complex structures or splicing designs, hand sewing can ensure that the components are connected naturally and have smooth curves, giving the product a unique manual temperature, and meeting customers' dual needs for scarcity and quality.

2. Needle selection and structural design

The hand sewing of customized tote bags involves a variety of needle methods, such as flat needle seams, lock edge seams, dark needle seams, etc. Flat needle seams are often used for foundation splicing to ensure the fabric is firmly connected; locking seams can prevent the fabric edges from wear and improve durability; dark needle seams use hidden seams to make the surface of the tote bag look cleaner and more beautiful. In terms of structural design, suppliers need to adjust the sewing details according to the purpose of the tote bag (such as daily commuting and banquet matching). For example, a large-capacity tote bag needs to strengthen the suture density at the bottom and handle parts to enhance load-bearing capacity; while an exquisite dinner bag needs to create a smooth and traceless appearance through fine dark needle technology.

3. Craftsman skills and quality assurance

The quality of hand-sewn is highly dependent on the experience and skills of craftsmen. Customized tote bag suppliers usually train professional hand-sewing teams, requiring craftsmen to master sewing techniques of different materials, such as gentle processing of silk, hole-punching and reinforcement of leather, etc. At the same time, a strict quality inspection process is established to check the uniformity, needle distance and firmness of each suture to ensure that the product meets high-end quality standards. This persistence in craftsmanship and demand for details are the fundamental reason why hand-sewn tote bags can stand out and become a symbol of quality.

3. Fusing process: the perfect presentation of high-end texture

Tempering printing and hand-sewing do not exist in isolation, but rather they jointly shape the high-end texture of the customized tote bag through clever integration. During the design stage, suppliers need to comprehensively consider the characteristics of the two processes and organically combine the hot stamping pattern with the sewing structure. For example, in the splicing parts hand-sewn, outlining the outlines through the hot stamping lines can not only enhance the visual layering but also cover up the stitching marks; or embellish it with hand-embroidery around the hot stamping pattern to enhance the overall artistic sense. The collaborative application of this technology not only meets the customers' dual needs for functionality and aesthetics, but also makes the customized tote bag an artwork with both practical value and collection value.

For custom tote bag suppliers, the exquisite craftsmanship of hot stamping and hand sewing is the foundation for gaining a foothold in the high-end market. Only by constantly improving technology and innovative design and combining traditional craftsmanship with modern aesthetics can we continue to provide customers with customized products with excellent texture and gain a place in the fierce market competition.

中文简体

中文简体

English

English