The demand for sustainable and innovative energy solutions has been growing across multiple industries, including packaging, retail, and promotional sectors. One of the promising developments in this field is the emergence of eco-friendly printed batteries. These thin, flexible power sources offer new possibilities for illumination in products such as gift boxes and envelopes, transforming conventional packaging into interactive, visually engaging experiences.

The Rise of Eco-Friendly Batteries

Eco-friendly batteries represent a significant shift in energy storage technology. Unlike traditional batteries that rely heavily on toxic heavy metals and non-recyclable materials, eco-friendly batteries use safer materials and biodegradable components. Their low environmental impact, combined with lightweight and flexible design, makes them ideal for integration into delicate packaging materials such as paper, cardboard, and thin plastics.

Printed batteries, a subset of eco-friendly batteries, are fabricated through advanced printing technologies. These methods allow energy storage components to be directly applied onto substrates, resulting in ultra-thin, lightweight, and flexible devices. This flexibility enables innovative designs where energy storage does not compromise the aesthetics or form factor of the packaging.

Innovative Applications in Gift Boxes and Envelopes

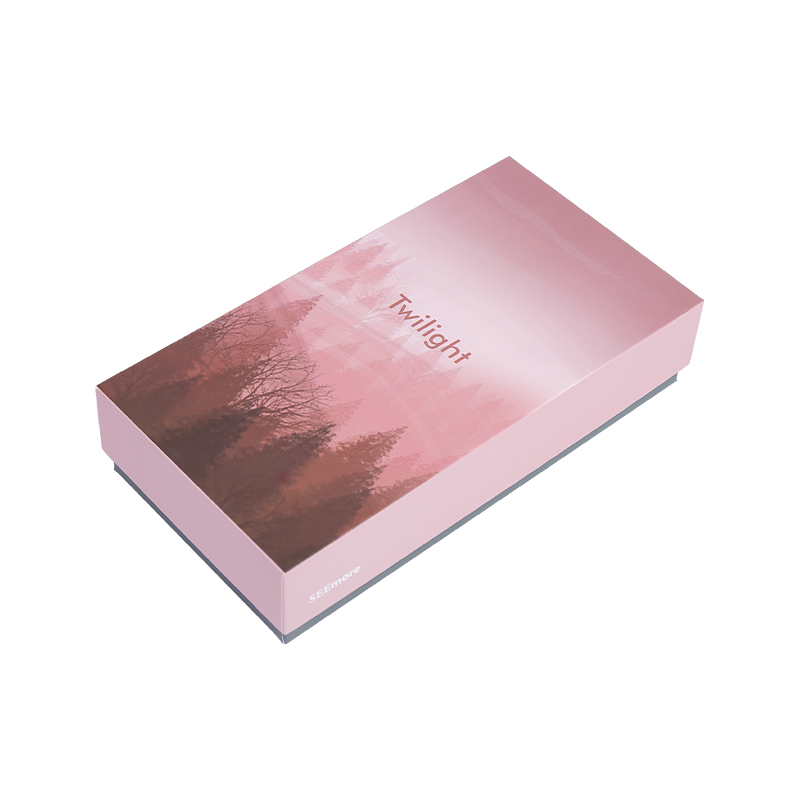

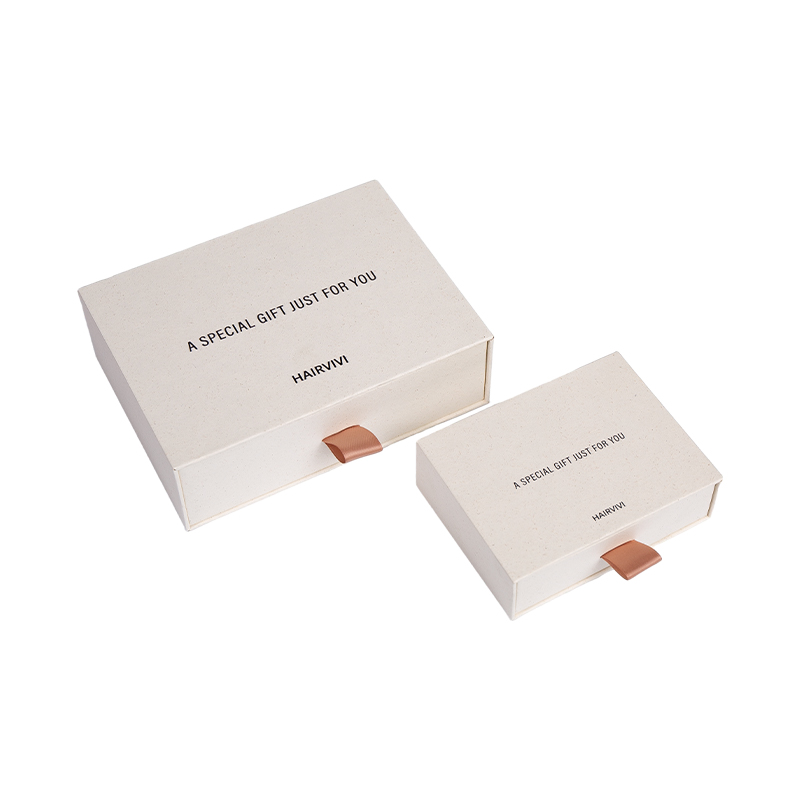

Gift boxes and envelopes are no longer limited to being containers; they have evolved into mediums for experiences. Integrating printed batteries into these items can transform traditional packaging into luminous and interactive presentations. By pairing printed batteries with low-power lighting elements, such as LEDs or electroluminescent inks, brands can create luminous labels and visual highlights that capture attention without the need for conventional power sources.

For example, a gift envelope equipped with a printed battery can illuminate upon opening, revealing a glowing message or pattern. Similarly, gift boxes can feature integrated luminous labels that light up to showcase product features or branding. The thin and flexible nature of printed batteries ensures that these innovations do not add bulk or weight, maintaining the premium feel of the packaging.

Key Benefits

| Feature | Description | Industry Impact |

|---|---|---|

| Flexibility | Can be printed on thin substrates | Suitable for envelopes, cards, and delicate packaging |

| Eco-friendly composition | Uses biodegradable or recyclable materials | Reduces environmental impact |

| Lightweight | Adds negligible weight | Maintains product aesthetics and shipping efficiency |

| Low power consumption | Supports small LEDs or luminescent inks | Extends battery life and reduces energy waste |

| Cost-effectiveness | Scalable printing techniques | Enables mass adoption without high production costs |

Driving Sustainable Energy Adoption

Sustainable energy is not confined to large-scale energy grids; it can also be implemented at micro scales. Printed batteries offer a sustainable solution for packaging, promotional materials, and disposable electronics. By integrating eco-friendly batteries into these small-scale applications, companies can reduce reliance on conventional batteries and support broader environmental goals.

Moreover, printed batteries align with the principles of circular economy. Materials can be recycled or safely decomposed, minimizing landfill contributions. This eco-conscious approach appeals to both businesses and consumers increasingly attentive to sustainability.

Technical Considerations and Manufacturing

The production of printed batteries involves a combination of materials science and printing technologies. Key elements include conductive inks, thin electrode layers, and electrolyte films, all designed to be compatible with flexible substrates. These batteries can be fabricated through roll-to-roll printing processes, which are scalable and efficient, allowing for high-volume production without excessive energy consumption.

Manufacturers need to consider several factors when integrating printed batteries into gift boxes and envelopes:

- Voltage and Capacity – Ensuring sufficient power to illuminate LEDs or electroluminescent inks for the intended duration.

- Mechanical Stability – Maintaining battery integrity during folding, bending, or shipping.

- Integration with Luminous Labels – Optimizing placement and connection to achieve uniform illumination.

- Safety and Compliance – Using non-toxic materials and meeting regulatory standards for consumer products.

Example Battery Specifications for Packaging Applications

| Specification | Typical Range | Notes |

|---|---|---|

| Voltage | 1.5–3.0 V | Suitable for low-power LEDs and EL inks |

| Thickness | 50–200 µm | Maintains flexibility and packaging aesthetics |

| Capacity | 5–50 mAh | Depending on illumination requirements |

| Lifetime | 1–6 months (storage) | Adequate for temporary promotional or gifting applications |

| Substrate Compatibility | Paper, cardboard, thin plastic | Enables direct integration into packaging |

Luminous Labels: A Transformative Element

Luminous labels are gaining traction as a creative marketing tool. When paired with printed batteries, these labels provide visual effects that attract attention and enhance user engagement. Unlike static labels, luminous labels can indicate interaction, reveal hidden messages, or highlight premium packaging elements. The combination of sustainable energy sources and innovative lighting designs ensures that brands can deliver memorable experiences without compromising on environmental responsibility.

Advantages of Luminous Labels with Printed Batteries

| Advantage | Impact on Packaging |

|---|---|

| Attention-grabbing | Enhances shelf presence and customer engagement |

| Energy-efficient | Minimizes power consumption and extends battery life |

| Customizable | Supports different colors, patterns, and messages |

| Lightweight | Does not increase shipping costs or packaging bulk |

| Eco-conscious | Reduces reliance on disposable, toxic batteries |

Conclusion

Eco-friendly printed batteries are transforming traditional concepts of illumination in gift boxes and envelopes. By combining flexible energy storage with luminous labels, these technologies provide a unique opportunity to deliver visually engaging, interactive, and environmentally responsible packaging solutions. The marriage of innovation and sustainability in this context is not only technically feasible but also commercially advantageous, offering brands a powerful tool to captivate audiences while reducing environmental impact.

FAQ

Q1: What is a printed battery?

A printed battery is a type of thin, flexible energy storage device produced through printing techniques, allowing direct application onto substrates such as paper, cardboard, or plastic.

Q2: How does an eco-friendly battery differ from traditional batteries?

Eco-friendly batteries use biodegradable or recyclable materials, avoiding toxic heavy metals, making them safer for the environment and reducing landfill waste.

Q3: Can printed batteries power standard LEDs in gift boxes?

Yes, printed batteries are designed to power low-energy devices such as LEDs or electroluminescent inks, sufficient for illumination in packaging and envelopes.

Q4: Are luminous labels with printed batteries safe for consumer products?

Yes, these systems use non-toxic materials and are designed to comply with safety standards, making them suitable for consumer applications.

Q5: What are the main benefits of integrating printed batteries in packaging?

Benefits include lightweight and flexible design, eco-friendly composition, energy efficiency, cost-effectiveness, and enhanced customer engagement through interactive lighting.

中文简体

中文简体

English

English