As an important "outer coat" of the product, corrugated color box gift box faces many harsh tests in transportation and storage. The heavy pressure and collision during stacking and handling can easily cause the packaging to deform or even damage, thereby threatening the safety of the items inside. How to effectively resolve these pressures through structural design and ensure that the corrugated color box gift box maintains integrity and functionality in a complex environment has become a key issue in the packaging field.

Analysis of the root causes of transportation and storage pressure

During transportation, corrugated color box gift boxes often have to go through the test of multi-layer stacking. Whether it is the tight stacking in the truck compartment or the stacking on the storage shelves, the packaging boxes below have to withstand the huge vertical pressure from above. During the handling process, forklift operations, manual handling and other operations will cause collisions and extrusions if they are not careful. These external forces act on various parts of the color box, posing a challenge to its structural strength. The uncertainty of the transportation environment will also continue to weaken the stability of the packaging box and increase the risk of damage.

Core strategy of compression-resistant structure design

In order to improve the compression resistance of corrugated color box gift box, double-layer corrugated structure has become an important solution. By rationally combining two layers of corrugated cardboard, a more resilient and strong overall structure is constructed. The flute type of the two layers of corrugated cardboard can be matched according to actual needs. For example, the outer layer uses A flute with strong compression resistance, and the inner layer uses B flute with good buffering performance. The two work together to resist external heavy pressure and effectively absorb impact. This double-layer structure allows the color box to evenly disperse the pressure during stacking, preventing local collapse and deformation due to excessive force. The setting of reinforcing ribs is also a key means to enhance compressive strength. By adding reinforcing ribs inside or on the edge of the box body of the corrugated color box gift box, a stable mechanical support frame is constructed. The reinforcing ribs can be made of the same or similar material as the corrugated cardboard, and are tightly combined with the box body by bonding, embedding, etc. They are like beams and columns in a building. Under the action of stacking pressure, they bear the main force task and transmit the pressure to the entire box structure to avoid stress concentration, thereby significantly improving the compression resistance of the color box. Whether it is the longitudinal or transverse reinforcement rib layout, it can effectively enhance the rigidity of the box body, so that it can still maintain a good shape under heavy pressure.

Optimization path for stacking stability

In addition to compression resistance, stacking stability is crucial for the performance of corrugated color box gift box in transportation and storage. Reasonable box design is the basis for ensuring stability. Compared with the special-shaped structure, the regular rectangular or cube box type has a larger contact area and a more uniform center of gravity distribution when stacking, which can effectively reduce the risk of tipping. The precise matching of the box cover and the box body should not be ignored. The tightly interlocking structural design can prevent the box body from being misaligned during the stacking process, ensuring that each layer of the box can stably support the weight above. In addition, some special anti-slip treatments, such as setting tiny bumps or textures on the surface of the box body, can increase the friction between the boxes, further improve the stacking stability, and reduce the sliding and displacement of the boxes even when the transport vehicle is bumpy.

Innovative design helps cope with pressure

With the continuous development of packaging technology, innovative design provides a new direction for corrugated color box gift box to cope with transportation and storage pressure. The modular structural design allows the packaging boxes to be combined and split according to actual needs, and the height and shape can be flexibly adjusted when stacking to adapt to different transportation scenarios. The foldable structure can greatly reduce the volume when not in use, which is convenient for storage and transportation, and can quickly restore the high-strength structure after assembly to meet the load-bearing requirements. The application of new materials has also brought breakthroughs in compression resistance and stacking stability. The new high-strength, low-density corrugated material reduces packaging weight and transportation costs while ensuring structural strength, and can better adapt to complex transportation and storage environments.

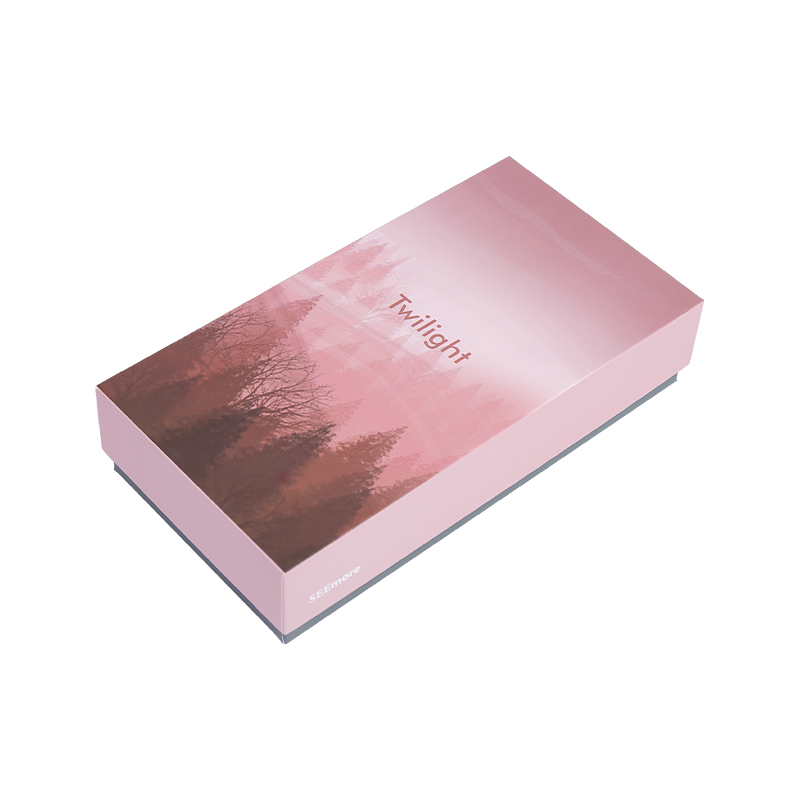

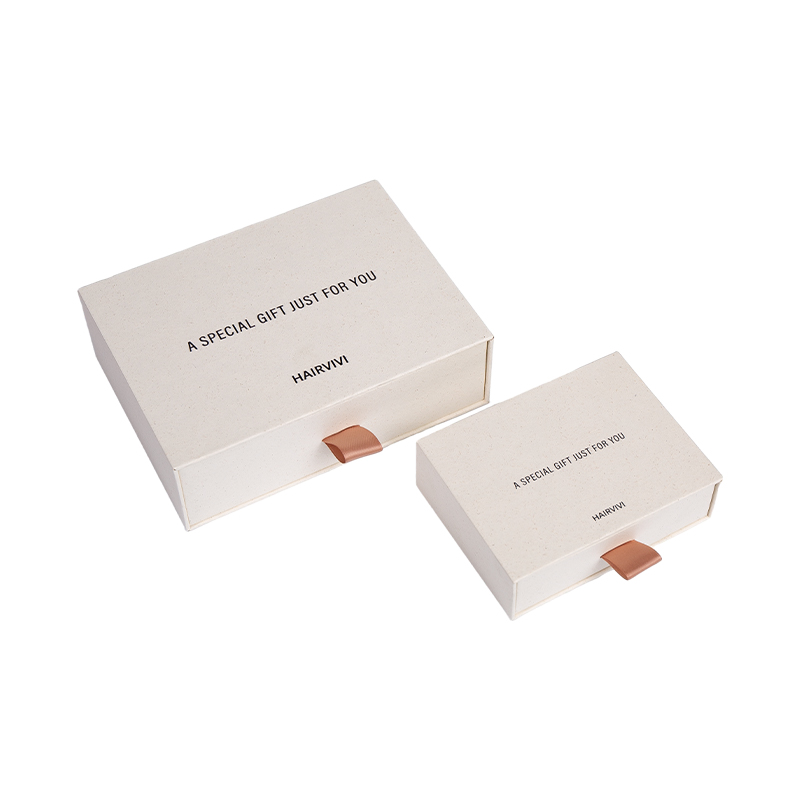

Structural Design of Corrugated Color Box Gift Box: Integration of Function and Aesthetics

Product Consultation

Search

Categories

Recent Posts

If you have any questions, please fill out the contact form and contact us.

中文简体

中文简体

English

English