Printing corrugated gift boxes use corrugated cardboard as the material. The material is a composite structure made of corrugated core paper and boxboard paper. Through the clever application of mechanical principles, it forms a packaging substrate with both cushioning performance and structural strength. The three-dimensional design of corrugated corrugation is like countless micro springs, which can effectively disperse pressure when impacted by external forces and provide a reliable protective barrier for internal items; and the composite structure of multi-layer paper gives it sufficient load-bearing capacity. Even in the face of packaging needs for large or heavy items, it can maintain a stable shape and avoid deformation and damage during transportation.

Applicable scenarios: A practical choice covering multiple packaging needs

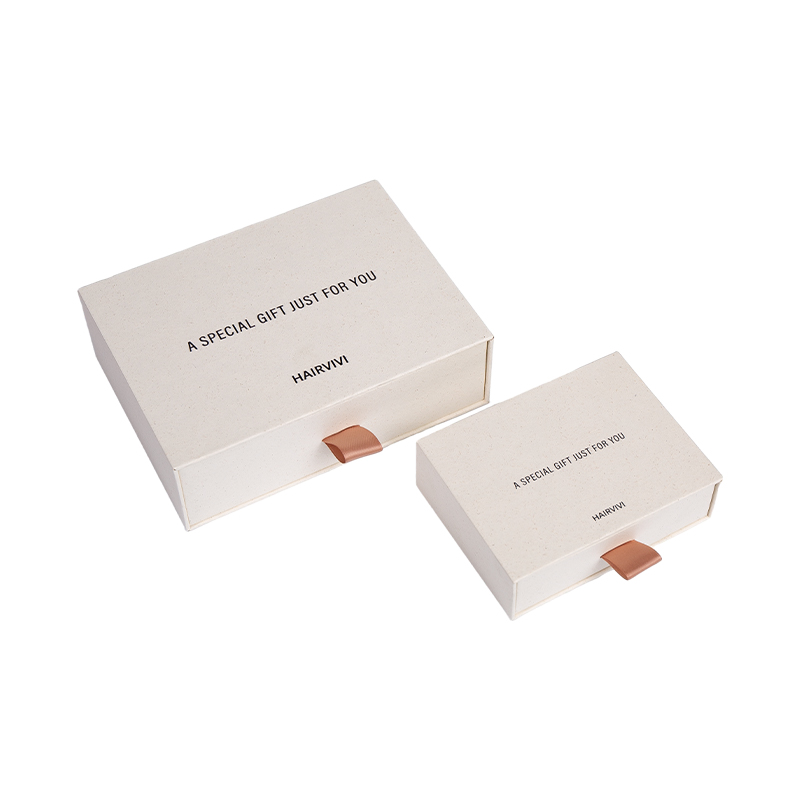

Based on the performance of the material itself, the applicable scenarios of printing corrugated gift boxes show significant diversity. For heavy items such as large household appliances and industrial parts, its high strength characteristics can ensure the integrity of the packaging during long-distance transportation or multiple handling; for fragile items such as glassware and ceramic products, its cushioning performance can minimize the risk of damage caused by collision; and in the field of fast-moving consumer goods, its characteristics of both protection and display not only meet the safety needs of product circulation, but also attract consumers' attention in terminal display. In the gift packaging scene, it can not only protect the gifts from damage, but also enhance the sense of ritual of the gifts through subsequent process treatment.

Printing process: injecting personalization and commercial value into packaging

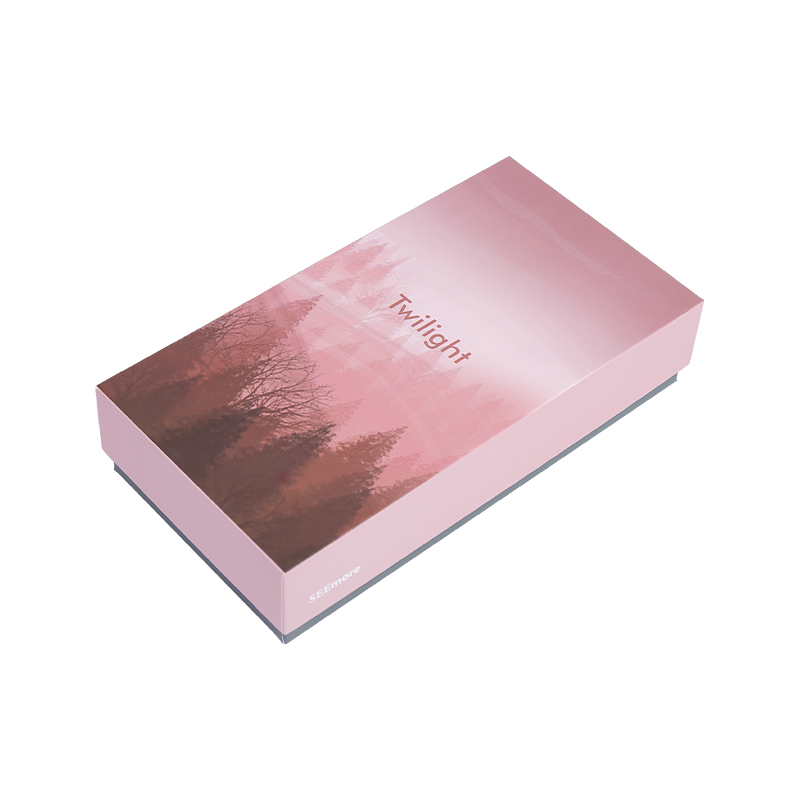

The application of printing process is the key feature that distinguishes printing corrugated gift boxes from ordinary corrugated packaging. Through sophisticated printing technology, rich visual elements can be presented on the surface of corrugated cardboard, including brand logos, product information, artistic patterns, etc. This process is not a simple pattern attachment, but through the control of ink characteristics and printing accuracy, it ensures that the pattern is full of color, clear lines, and can be integrated with the surface texture of the corrugated cardboard, which does not destroy the original structural strength of the material and enhances the overall visual texture. Personalized printing design can not only make the packaging an extension of the brand image and strengthen consumers' awareness of the brand, but also be customized according to the theme and style of different gifts, so that the packaging and gifts can echo each other, enhance the emotional expression in the gift delivery process, and thus invisibly combine the practical value of the packaging with the commercial value.

Size design: taking into account both space utilization and visual appeal

The size and shape design of the gift box reflects the balance between functionality and aesthetics. According to the specifications of different commodities, through precise measurement and cutting, the packaging and the items can be perfectly matched, avoiding the increase in transportation costs caused by space waste, while reducing the shaking of the items inside the packaging, and further improving the protection effect. In terms of shape design, breaking through the single form of the traditional rectangular parallelepiped, combining the characteristics of the gift to create a special-shaped structure, can not only optimize the space utilization rate, but also form a unique visual appearance and enhance the attractiveness of the packaging. For gifts with irregular shapes, through special folding and splicing processes, the packaging can fit the outline of the item and present a novel appearance.

Assembly characteristics: practical advantages of improving packaging efficiency

The convenience of printing corrugated gift boxes in the assembly process adds significant advantages to its practical application. Thanks to the reasonable structural design, the connection between its components is simple and clear, without the need for complex tools or professional skills. Operators can quickly complete the assembly through simple folding, plugging and other steps. This efficient assembly process not only saves a lot of time costs, but is also particularly suitable for scenarios where the order volume in the gift industry fluctuates greatly, and can quickly respond to short-term surges in packaging demand; at the same time, it also reduces the requirements for manual skills, reduces training costs and operational error rates. For companies, this feature means that higher production efficiency can be achieved in the packaging process, shortening the cycle from packaging to delivery, and indirectly improving the speed of the overall supply chain, making printing corrugated gift boxes a cost-effective packaging option while taking into account both quality and aesthetics.

A Comprehensive and Professional Analysis of Printing Corrugated Gift Boxes

Product Consultation

Search

Categories

Recent Posts

If you have any questions, please fill out the contact form and contact us.

中文简体

中文简体

English

English