From the precise presentation of printing technology, to the exquisite combination of materials and patterns, to the ingenious production process, each process of luxury printed tote bags tells the quality code of luxury goods and explains how artistic ideas are implemented as classic items.

Technology-enabled artistic rebirth

The soul of luxury printed tote bags lies in the fusion of patterns and bag surfaces, and the two core processes of digital printing and screen printing are achieving this goal with completely different technical paths. With its precise digital control, digital printing technology transfers every stroke and every color in the design draft to the fabric with micron-level precision. Whether it is the delicate texture of oil painting or the rich gradient colors, the high-speed operation of the digital nozzle can faithfully restore the designer's creative ideas, ensuring that the pattern always maintains a clear and sharp visual effect on different sizes and materials. Screen printing stands out with its unique touch and three-dimensional effect. The ink is squeezed through the screen by a scraper, and the ink forms a slightly raised texture on the surface of the fabric. This physical superposition gives the pattern a unique sense of relief. Under the refraction of light, the raised part of the ink forms a light and dark contrast with the plane, making the floral, geometric and other patterns appear vivid on the bag, injecting dynamic artistic tension into the static printing. The two processes together create a visual feast of luxury handbags.

Symphony of texture and aesthetics

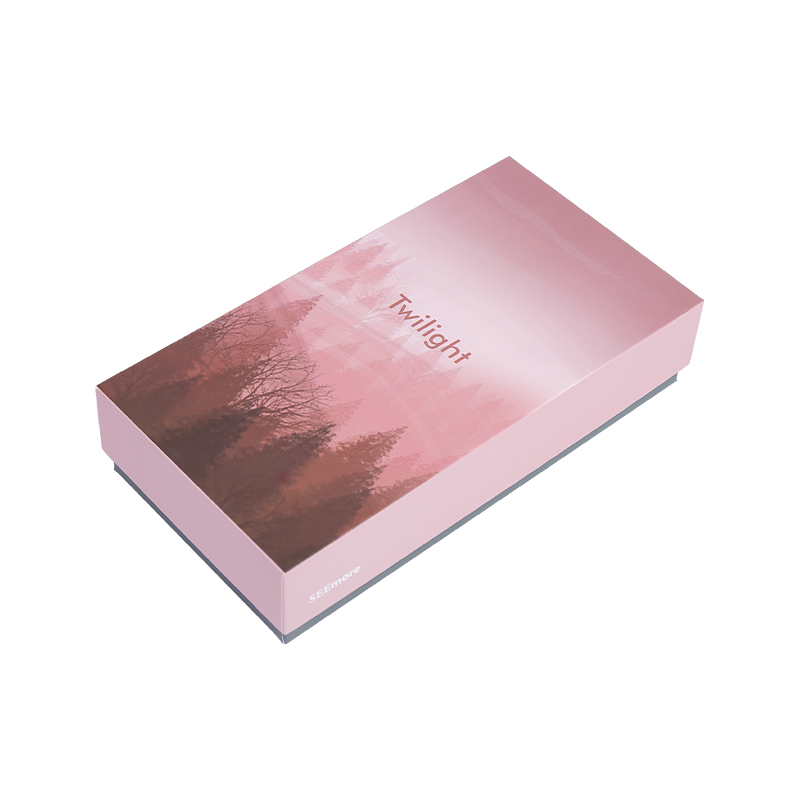

Material selection is another key dimension of the luxury printed tote bags process system. The physical properties and visual language of different fabrics form a deep dialogue with the printed patterns, creating a rich aesthetic experience. Calfskin has become a classic choice for high-end handbags with its delicate texture and soft touch. Its natural lines and printed patterns are intertwined, which not only highlights the exquisiteness of the pattern, but also retains the original texture of the leather, giving the product a low-key and luxurious style; silk, with its smooth surface and soft luster, provides a canvas for printing, making the colors present a glittering effect, especially suitable for expressing delicate ink and watercolor style patterns, showing elegance and romance; canvas, with its rough and tough characteristics, collides with abstract and street-style prints to create a unique sense of fashion, and its wear-resistant characteristics give the product practical value, achieving a balance between aesthetics and function. The matching of fabrics and prints is not a simple superposition, but a systematic consideration based on the design theme. Designers need to comprehensively consider the color saturation, line complexity and overall style of the pattern to choose the fabric characteristics that match it. Retro oil painting-style prints are more suitable for the heavy texture of calfskin, while fresh watercolor floral patterns complement the lightness of silk. This precise matching allows the material and prints to complement each other and jointly interpret the design concept.

Quality adherence in details

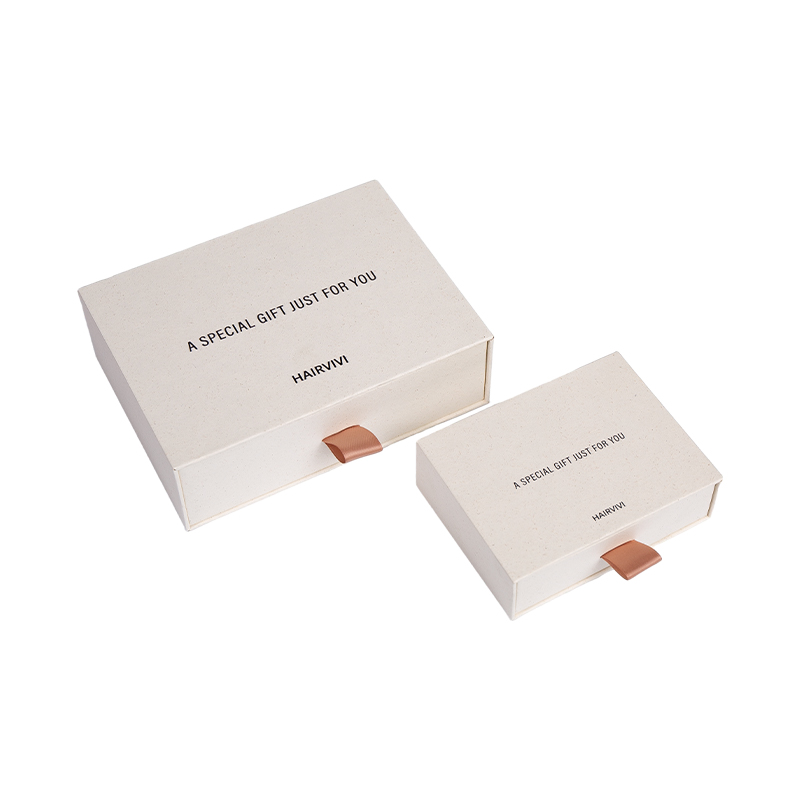

From design drawings to finished products, the birth of luxury printed tote bags embodies countless ingenious details. In the cutting process, craftsmen must strictly plan the cutting pieces according to the symmetry and integrity of the pattern to ensure that the pattern after splicing is coherent and natural; during the sewing process, the density of the lines and the uniformity of the stitches are precisely controlled to ensure that the structure of the bag is firm and the integrity of the printed pattern cannot be destroyed; the selection and installation of accessories are also exquisite, the color of the metal fasteners and the smoothness of the zipper must be highly consistent with the overall style, and even the material and printing details of the lining are carefully designed to ensure the same quality inside and outside. Every production step undergoes a strict quality inspection process, from the color fastness test of the fabric printing to the durability test of the bag body, any minor defects will be corrected in time. This pursuit of details is a commitment to quality and a concrete expression of the brand's ingenuity.

Ingenuity: The Advanced Craftsmanship Aesthetics of Luxury Printed Tote Bags

Product Consultation

Search

Categories

Recent Posts

If you have any questions, please fill out the contact form and contact us.

中文简体

中文简体

English

English